Building 2, Dongfang Mao Commercial Center, Hangzhou, Zhejiang, China +86-18858136397 [email protected]

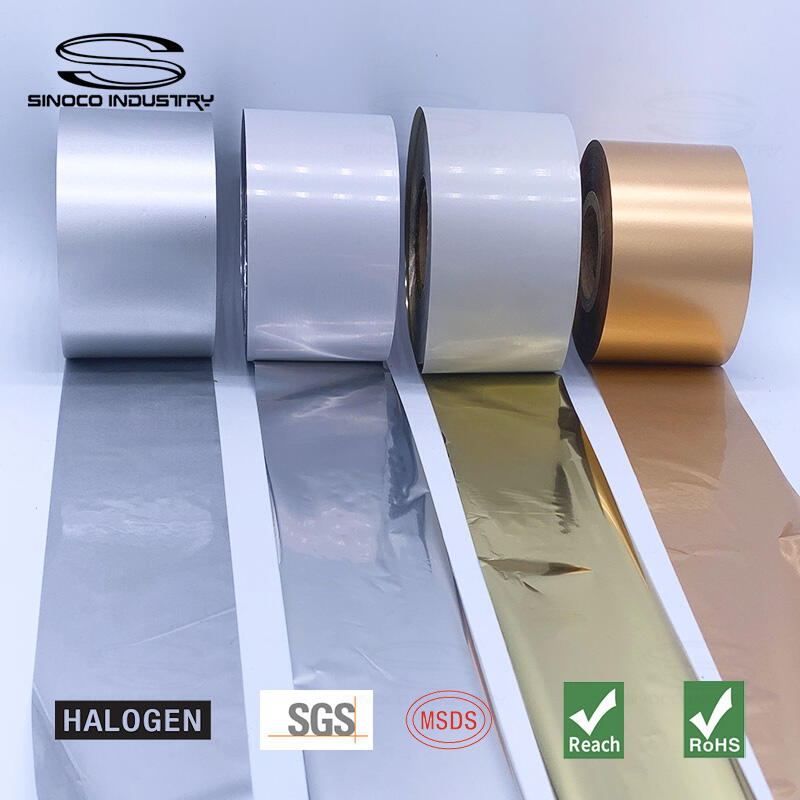

Coding foil production is a precise, multi-stage process integrating advanced technology and strict quality control. It starts with raw material inspection: base polyester films are checked for thickness uniformity, release agents for purity, and pigments/binders for consistency—impurities here cause coating defects. Next is coating: using equipment like 10-coater, layers (release, transfer) are applied evenly, with thickness controlled to micrometers. Different techniques (knife coating for smoothness, gravure for high pigment density) suit product needs. Drying/curing follows: solvents are removed, and binders cross-link; temperature/time are critical—excess heat damages the base film, insufficient drying weakens adhesion. Slitting/rewinding then cuts jumbo rolls into client-specified sizes, with precision equipment ensuring clean edges to avoid printing jams. Throughout, quality control is constant: coating thickness is measured, adhesion tested via tape peeling, and color checked for accuracy. ISO-certified facilities guarantee batch consistency. Customization is key: adjusting pigment ratios for unique colors or modifying binders for wash resistance meets industry demands. For example, pharmaceutical coding foil needs high-temperature resistance, so production tweaks the transfer layer formula. Post-production, rolls are packaged to protect from moisture/dust. Hangzhou Sinoco Industry Co., Ltd. optimizes each step, using its R&D to refine processes. From raw material to packaging, the process ensures coding foil works with various printers and substrates, supporting seamless production for clients.