Building 2, Dongfang Mao Commercial Center, Hangzhou, Zhejiang, China +86-18858136397 [email protected]

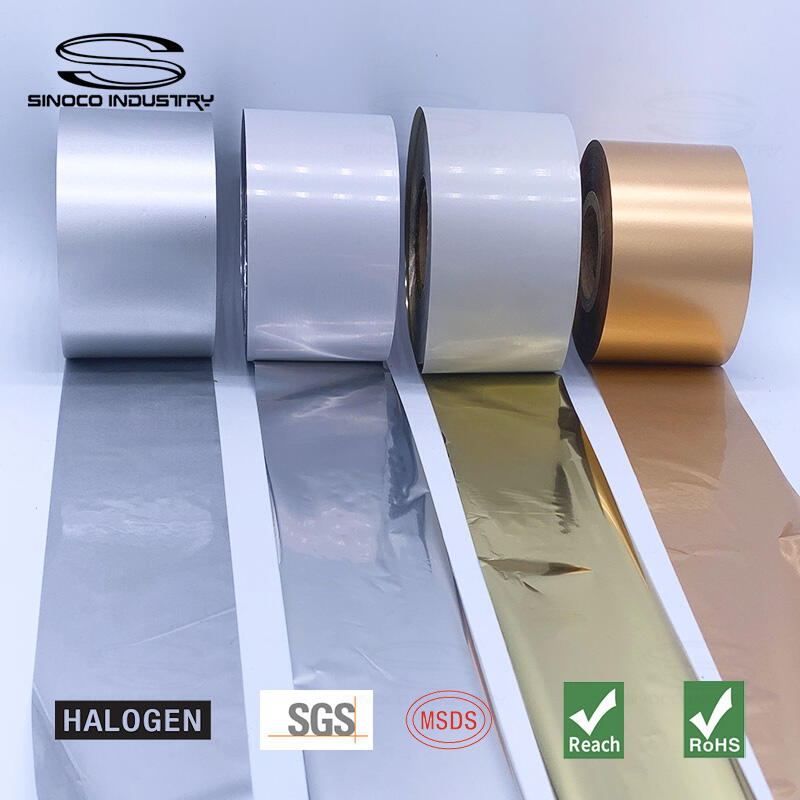

Coding foil code refers to the specific information imprinted onto a surface, most commonly ribbon or labels, using a coding foil printer and hot stamping foil. This code typically consists of variable data such as sequential serial numbers, manufacturing dates, expiration dates, batch or lot numbers, shift codes, and sometimes machine identifiers. The primary functions of these codes are to ensure product traceability throughout the supply chain, facilitate efficient recall management if necessary, comply with industry regulations, prevent counterfeiting, and maintain inventory control. The code is created by a foil die, which can be a rotary type with adjustable characters for changing information or a fixed die for static text like a logo. The foil itself is available in various colors (gold, silver, black, red, etc.) and types (e.g., scratch-off foils for security) to ensure high visibility and contrast on different background materials. For instance, in the pharmaceutical industry, a satin ribbon used to seal product packages may be hot-stamped with a black foil code indicating the drug's batch number and expiration date, providing critical information for safety and compliance. In the food industry, a polypropylene ribbon might be coded with a silver foil imprint showing the packaging date. The quality of the code is essential; it must be consistently legible, durable, and resistant to environmental factors like moisture or abrasion. The design and implementation of an effective coding system require careful planning to meet regulatory standards and operational needs. We offer solutions and materials related to industrial coding. For specific information on implementing a coding system with foil and to discuss the requirements for your application, please contact our technical support team for a professional consultation.