Building 2, Dongfang Mao Commercial Center, Hangzhou, Zhejiang, China +86-18858136397 [email protected]

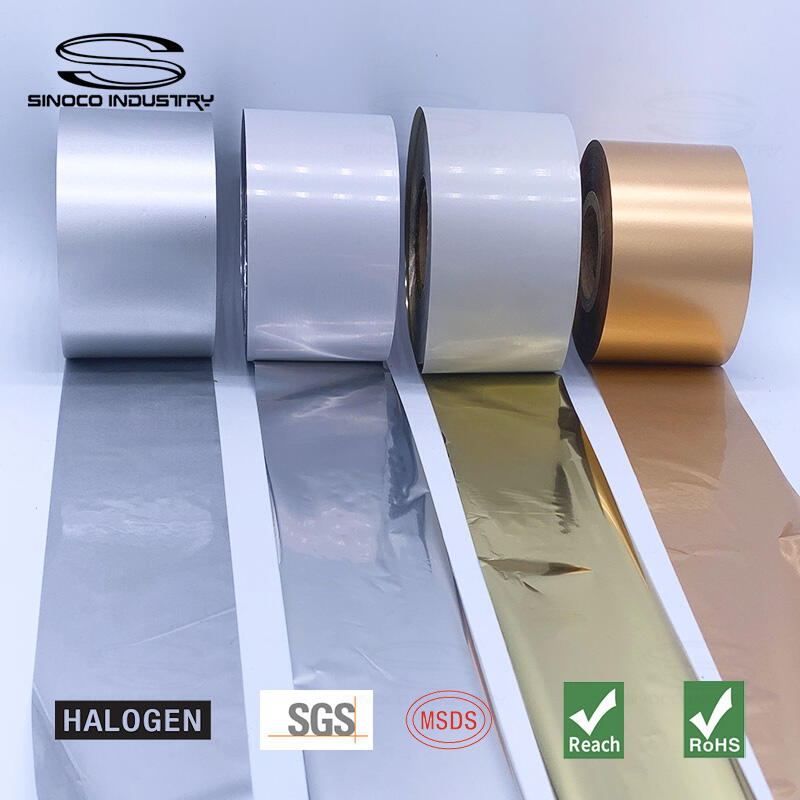

Coding foil encompasses diverse types, each designed for specific needs. Black thermal transfer ribbon is the most common—used for general labeling (batch numbers, expiration dates) in food, logistics, and retail, offering clear readability and compatibility with most substrates. Color ribbon includes standard shades (red, green, blue) for color-coded categorization—e.g., red for “expired” in pharmaceuticals, green for “safe” in food, aiding quick identification. Metallic color ribbon (gold, silver, blue, green, rose, yellow) suits premium branding—used on cosmetic packaging, luxury goods, and craft products to enhance visual appeal. UV security ribbon has UV-reactive properties, used in pharmaceuticals and luxury goods to prevent counterfeiting—visible under UV light, verifying authenticity. TTO near-edge ribbon is for high-speed printing (up to 12IPS) in production lines—ideal for fast-moving industries like beverage bottling, ensuring efficient coding without delays. Hot stamping foil (coding foil) is used for permanent marking on plastic, paper, and fabric—heat-activated transfer ensures strong adhesion. Washcare resin ribbon (e.g., SNR6900) is for textiles—withstanding multiple washes, used on clothing care labels. Wax-resin ribbon (e.g., SNM2800, SNM2600) balances wax’s low energy use and resin’s durability—SNM2800 offers high scratch resistance for logistics, SNM2600 has chemical resistance for harsh environments. Wax ribbon (e.g., SNW1300) is cost-effective for paper labels, providing clear barcodes. Hangzhou Sinoco Industry Co., Ltd. offers all these types, with customization to match client needs—ensuring each type delivers optimal performance for its application.