Building 2, Dongfang Mao Commercial Center, Hangzhou, Zhejiang, China +86-18858136397 [email protected]

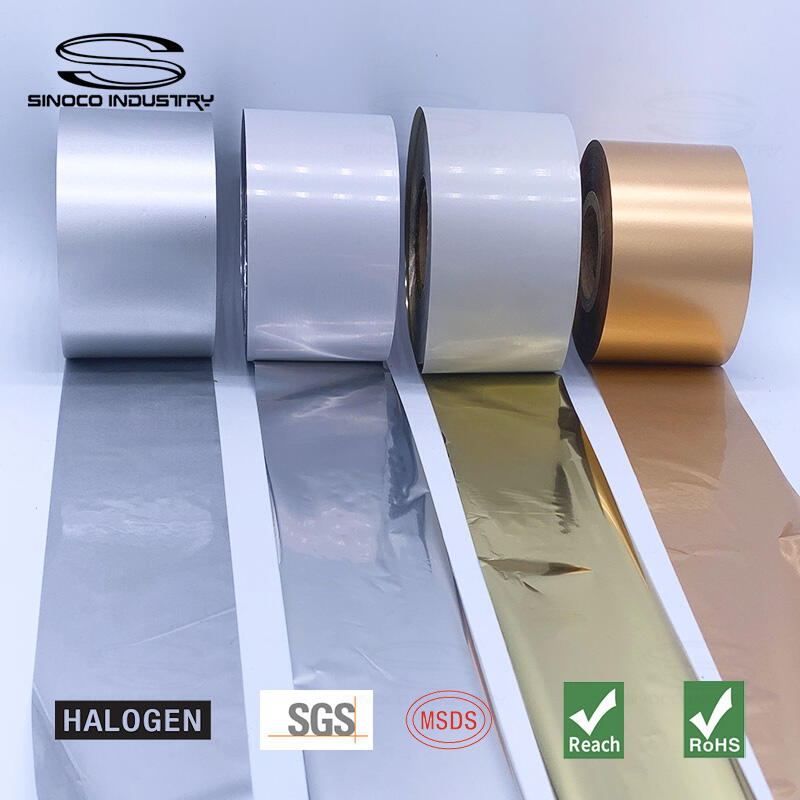

Coding foil quality is defined by key factors: adhesion, durability, color consistency, and substrate compatibility. Adhesion ensures the foil transfers firmly to substrates (plastic, paper, fabric)—tested via tape peeling; poor adhesion leads to smudging or code loss. Durability includes abrasion resistance (withstanding handling in logistics), wash resistance (for textiles), and heat resistance (surviving sterilization in pharmaceuticals)—high-quality foil maintains readability in harsh conditions. Color consistency ensures batch-to-batch uniformity—critical for branding (e.g., a cosmetic firm’s metallic gold must not vary). Substrate compatibility means the foil works with the client’s material—e.g., nylon needs SNR6900 washcare resin foil, paper uses SNW1300 wax foil. Quality control starts with raw materials: inspecting polyester films for thickness, pigments for purity. During production, coating thickness is measured, drying is monitored, and finished rolls are tested for performance. ISO certification guarantees consistent quality. Hangzhou Sinoco Industry Co., Ltd. prioritizes quality—its R&D team tests foil under real-world conditions (moisture, heat, washing) to ensure reliability. For example, SNM2800 is tested for scratch resistance on logistics labels, SNR6900 for wash resistance on textiles. The company’s after-sales support addresses quality concerns, ensuring clients get foil that meets their standards. High-quality foil reduces printing errors, lowers waste, and ensures compliance with industry regulations.