Building 2, Dongfang Mao Commercial Center, Hangzhou, Zhejiang, China +86-18858136397 [email protected]

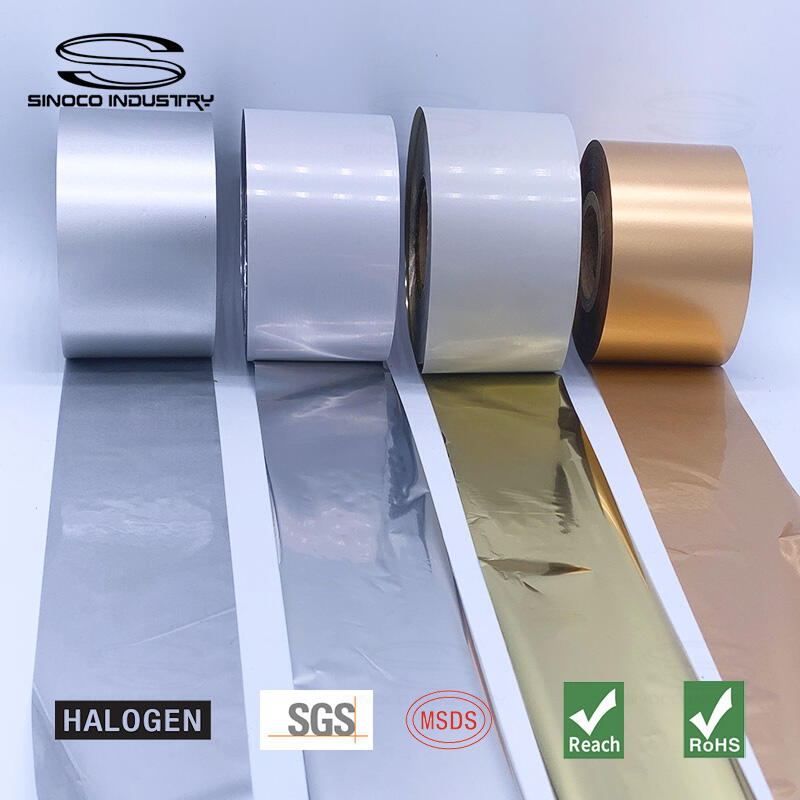

Coding foil material is a multi-layer composite structure that directly determines the performance, applicability, and durability of coding foil. The base layer, usually made of high-quality polyester film, provides structural support, requiring excellent tensile strength and dimensional stability to resist deformation during coating and printing. This is vital for high-speed production lines, as any base layer failure can cause printing interruptions. The release layer, applied on the base film, uses specialized release agents to ensure the transfer layer separates smoothly from the base during hot stamping; improper release properties lead to incomplete code transfer or base film residue. The transfer layer is the core, consisting of pigments, binders, and additives. Pigments define color—from standard black for clear coding to metallic gold/silver for premium packaging—while binders ensure adhesion to substrates like plastic, paper, or fabric. Additives such as UV stabilizers enhance outdoor durability, and wash-resistant components suit textile washcare labels. For food packaging, materials must be non-toxic and meet food safety standards to avoid contamination. In electronics, heat-resistant binders prevent coding damage during soldering. Hangzhou Sinoco Industry Co., Ltd. selects materials rigorously, with its R&D team testing combinations to match industry needs. Whether for high-temperature sterilization in pharmaceuticals or moisture resistance in logistics, the company’s material focus ensures coding foil performs reliably. Clients with unique needs, like eco-friendly or specialized heat-resistant materials, can access customized solutions via the company’s expertise.