Building 2, Dongfang Mao Commercial Center, Hangzhou, Zhejiang, China +86-18858136397 [email protected]

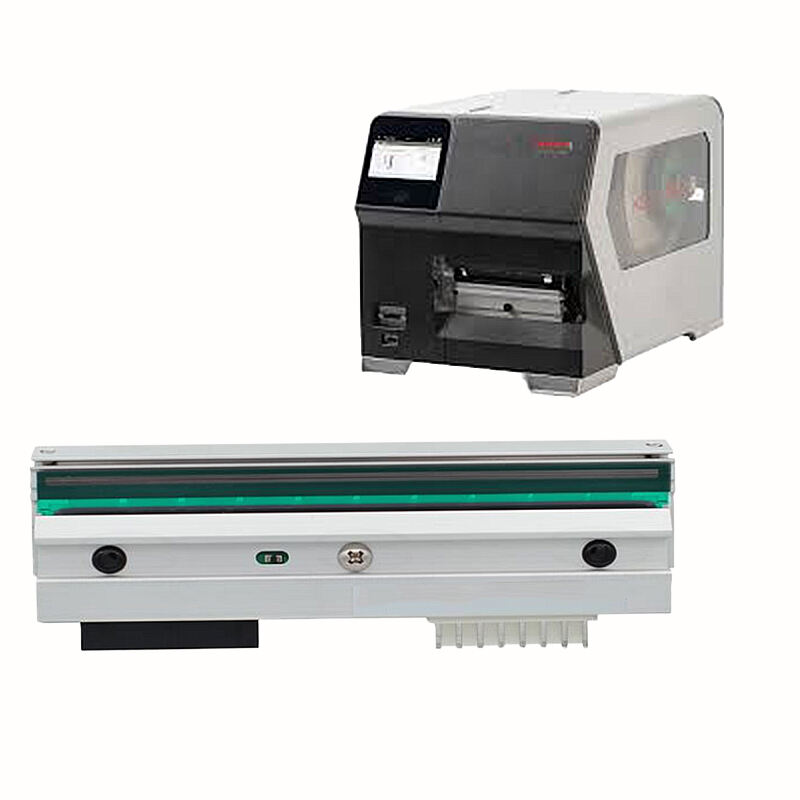

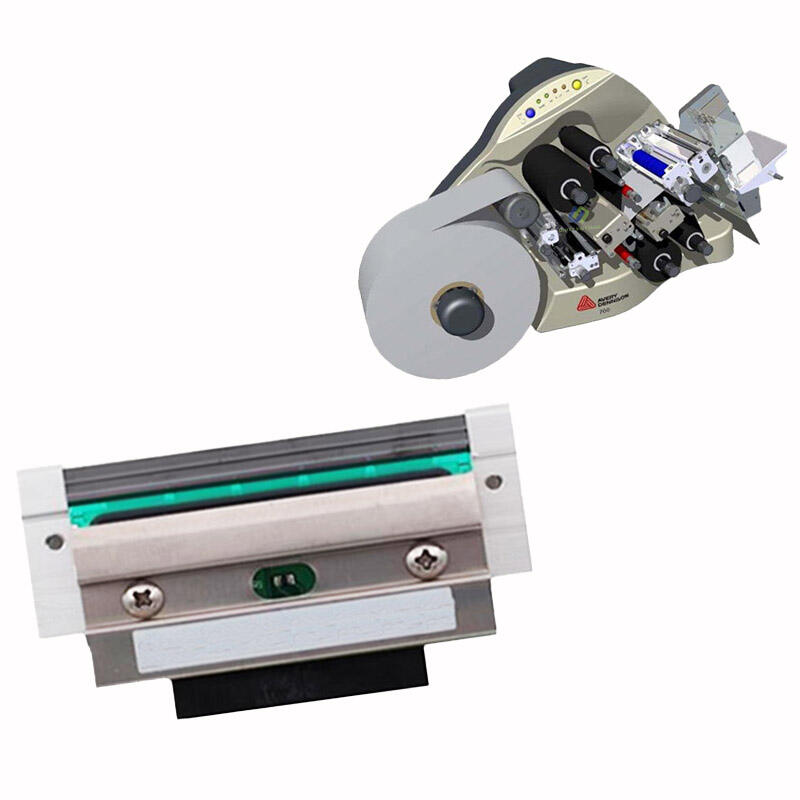

Ribbon printer application encompasses the vast array of use cases where thermal transfer printers are utilized to create durable, high-contrast images, text, and barcodes on label stock, tags, and wristbands. The fundamental technology involves heating elements within the printhead selectively melting ink from a wax, wax-resin, or pure resin ribbon onto the surface of the media, resulting in a permanent mark highly resistant to abrasion, chemicals, and environmental exposure. In the logistics and supply chain sector, these printers are applied to generate shipping labels, pallet tags, and compliance labels that must remain scannable throughout the entire distribution journey, enduring friction, handling, and variable weather conditions. Within manufacturing and electronics, printers are applied for printing UL/CE certification labels, component identification tags, and serialized QR codes for track-and-trace purposes directly on the production line. The healthcare industry applies ribbon printers for creating patient wristbands with barcodes for positive identification and for printing laboratory specimen labels that resist exposure to liquid nitrogen or chemical solvents. Retail applications include printing price markings, garment tags, and shelf labels that require a crisp, high-resolution appearance. The specific application dictates the choice of printer model, print resolution (e.g., 203 dpi, 300 dpi, 600 dpi), and the type of ribbon required. To determine the optimal printer configuration and ribbon formulation for your specific application challenges, please contact our application engineering team for expert guidance and support.