Building 2, Dongfang Mao Commercial Center, Hangzhou, Zhejiang, China +86-18858136397 [email protected]

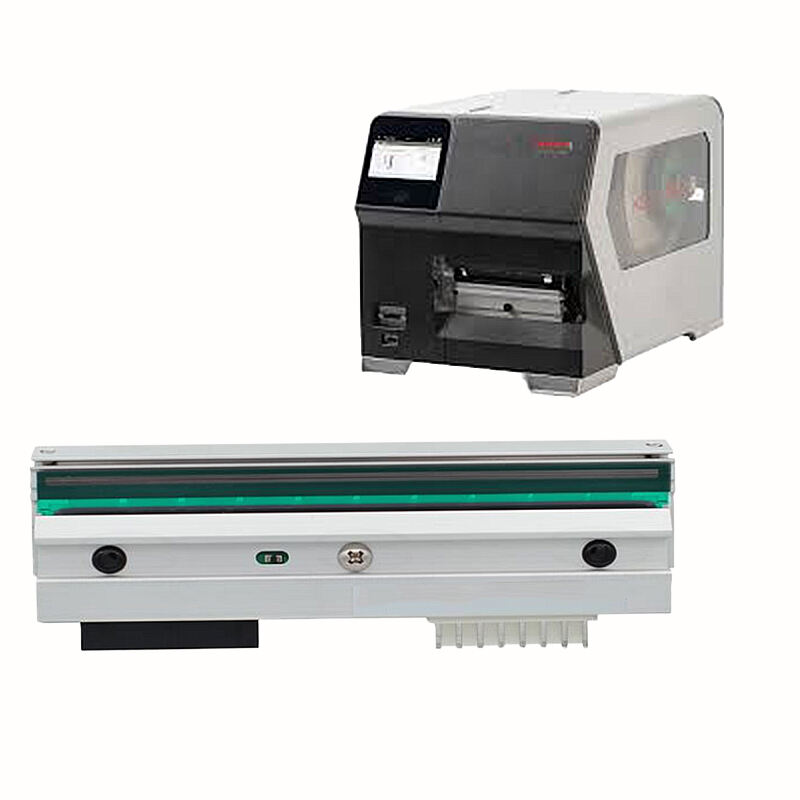

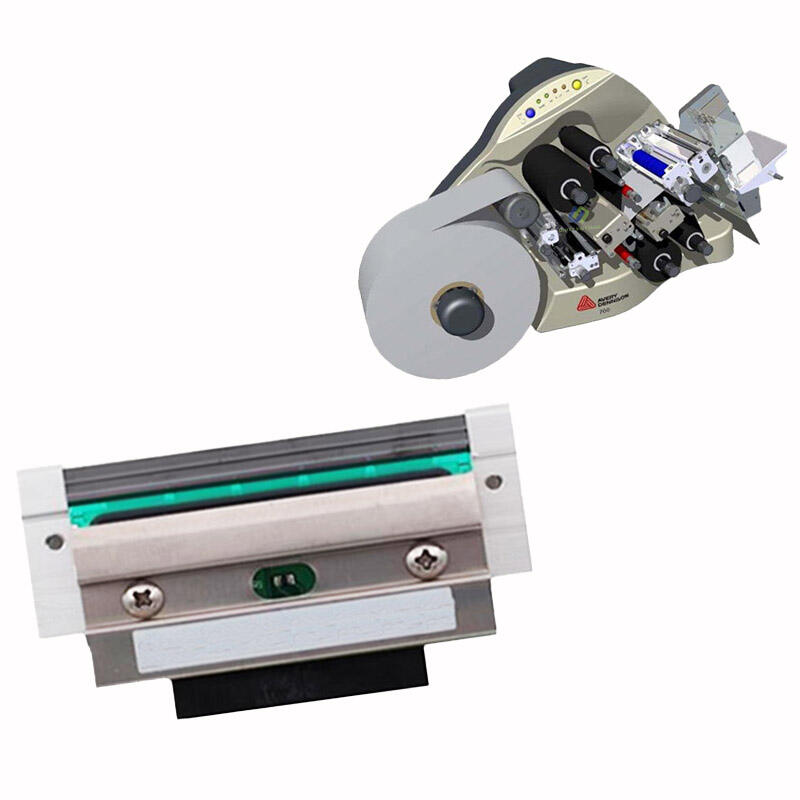

Ribbon printer quality is a multifaceted attribute defined by its mechanical durability, printhead longevity, consistent performance, and operational reliability under sustained workloads. A high-quality printer is engineered with a robust metal chassis and internal components, such as precision stepper motors for accurate media feed, which prevent misalignment and jamming during continuous operation. The quality of the printhead, often featuring diamond-coated or hardened glass protection layers, is paramount as it directly impacts print clarity and service life, capable of producing millions of inches of print without degradation. Consistency is another critical quality metric; a superior printer delivers uniform print density across the entire label width, batch after batch, ensuring every barcode achieves a high-grade scanability rating. Reliability is demonstrated through mean time between failures (MTBF) ratings, with quality printers often exceeding 10,000 hours of operation, minimizing costly downtime in automated production or warehouse environments. These printers incorporate advanced thermal control systems that dynamically adjust printhead energy to compensate for varying print speeds and ambient temperatures, preventing voids or smudging. Quality is also reflected in the user experience through intuitive software, easy-loading mechanisms, and comprehensive diagnostics that simplify maintenance. For industries where print quality is non-negotiable, such as aerospace part marking or pharmaceutical serialization, investing in a printer built to exacting quality standards is essential. We invite you to inquire about our quality testing protocols and performance data sheets to understand the superior reliability our printers offer.