Building 2, Dongfang Mao Commercial Center, Hangzhou, Zhejiang, China +86-18858136397 [email protected]

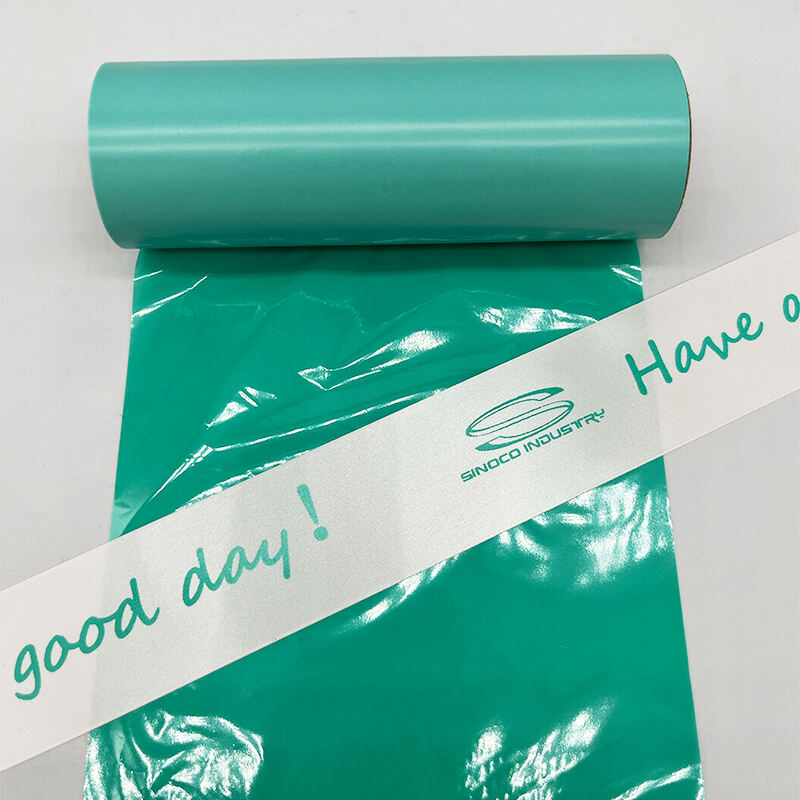

A color ribbon manufacturer is an industrial entity engaged in the primary production of ribbon, controlling the process from sourcing raw materials (yarns, dyes, chemicals) to transforming them into finished, colored ribbon products through various processes like weaving, knitting, dyeing, printing, and finishing. Manufacturers operate extensive facilities with specialized machinery such as shuttle looms, needle looms, dyeing vats, printing machines, and coating equipment. Their core expertise lies in textile engineering, color science, and production efficiency. They produce ribbon in massive volumes, typically on large beams, which are then wound onto smaller spools for sale to wholesalers, converters, or large end-users. A manufacturer's capabilities are defined by the types of ribbon it can produce (woven, satin, grosgrain, jacquard, etc.), its dyeing techniques (solution dyeing for superior colorfastness vs. piece dyeing), and its printing technologies. They work with a vast array of fiber types including polyester, nylon, cotton, polypropylene, and rayon. For example, a manufacturer might produce a custom-dyed, flame-retardant nylon ribbon for automotive applications, followed by a run of brightly colored polyester satin ribbon for the craft market. Manufacturers often engage in both B2B sales of bulk unfinished ribbon (greige goods) to converters and finished goods under their own brand or for private label clients. They are the source of innovation in the industry, developing new weaves, eco-friendly materials, and advanced finishes. We are a established manufacturer with integrated production capabilities for color ribbon. For businesses seeking manufacturing partnerships, OEM production, or information about our core manufacturing competencies, please contact our production management team for technical discussions and feasibility assessments.