The Environmental Impact of Traditional Thermal Transfer Ribbon Production

How Conventional Manufacturing Contributes to Pollution and Waste

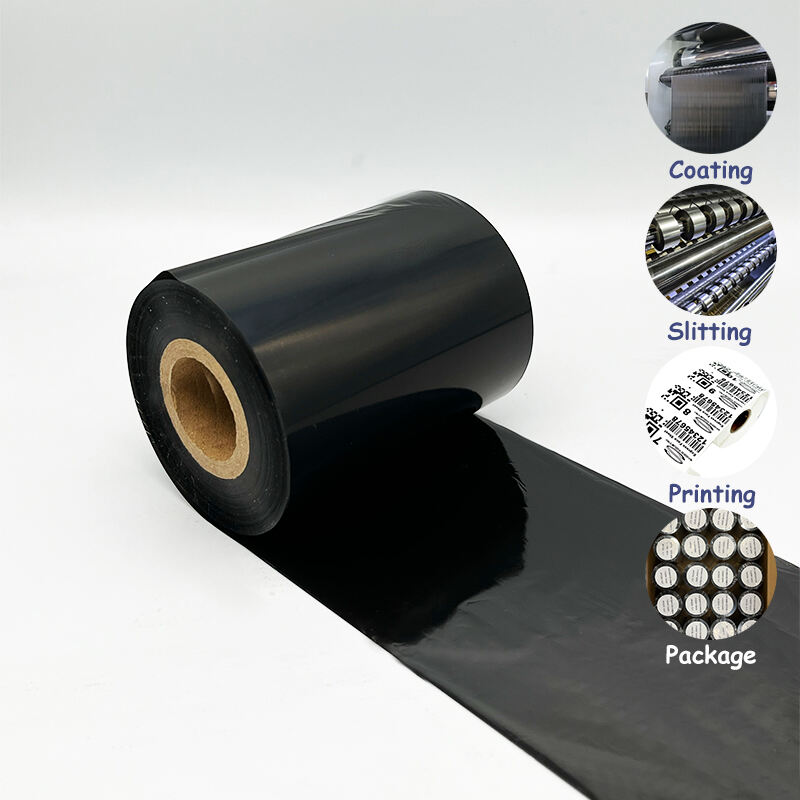

Most traditional methods for making thermal transfer ribbons still depend on those plastic cores that just won't break down, plus they use ink loaded with chemicals. According to some research published last year, around two thirds of all these old ribbons just get tossed into landfills. And there's a problem because stuff like phthalates in them can slowly seep into groundwater systems over months and years. The factories themselves are creating quite a mess too. We're talking somewhere between eight and twelve tons of microplastic waste every single month just from their coating processes. That kind of output adds up pretty fast when looking at multiple facilities across different regions.

Carbon Footprint and Resource Consumption in Standard Production Processes

Specialty printing is responsible for about 22 percent of carbon emissions in the industry because of all the energy needed for melting and coating operations. Just think about this: making a single metric ton of ribbon takes around 14 megawatt hours of electricity, which would power roughly 1,300 average homes for an entire day. Looking at waste management data from around the world shows some alarming figures too. American landfills collect approximately 35 million tons of plastic garbage each year, and thermal transfer ribbons alone make up nearly 18% of what gets thrown away in industrial labeling applications across factories and warehouses nationwide.

Growing Demand for Sustainable Alternatives in Labeling Industries

Driven by corporate ESG commitments, 67% of packaging manufacturers now prioritize suppliers offering biodegradable ribbon options. In the healthcare sector, adoption of eco-friendly ribbons has surged 140% since 2021, reflecting tighter regulations on hazardous materials in medical labeling.

Innovations in Biodegradable, Recyclable, and Low-Emission Ribbon Materials

Advances in Biodegradable Thermal Transfer Ribbon Formulations

Recent breakthroughs in plant-based resin blends and mineral-reinforced wax compounds enable ribbons to decompose 34% faster than conventional versions while maintaining print durability (2023 Material Degradation Report). By replacing petroleum-derived polymers with algae-extracted binders, manufacturers retain adhesion during shelf life but allow enzymatic breakdown after disposal.

Recyclable Substrates and Cores: Reducing Waste in Ribbon Design

Switching to recycled PET cores and cellulose-based spindles has diverted 18,000 metric tons of plastic waste annually from landfills. Thin-film architectures using 23% less polyester—without sacrificing tensile strength—show how sustainable substrate engineering reduces material use across production cycles.

Challenges in Achieving True Compostability Without Sacrificing Performance

Although 72% of biodegradable ribbon prototypes pass industrial composting tests, only 14% meet archival-grade permanence standards (International Printing Standards Association, 2023). Balancing decomposition rates with long-term chemical stability remains a key challenge, especially for applications in healthcare and automotive sectors requiring legibility for over a decade.

Emerging Low-Emission Technologies in Eco-Friendly Ribbon Production

Solvent-free coating systems now reduce volatile organic compound (VOC) emissions by 92% compared to traditional methods. Hybrid drying techniques combining infrared curing with air filtration enable energy-efficient manufacturing at scale while eliminating ozone-depleting byproducts, as detailed in the 2024 Footwear Materials Report.

Sustainable Wax/Resin Hybrid Solutions: Balancing Performance and Ecology

Eco-Conscious Formulations That Maintain Print Durability and Clarity

The manufacturing of thermal transfer ribbons has started incorporating more plant based resins along with recycled wax materials lately, all while keeping the same level of quality we've come to expect. According to research published in 2024, these new formula combinations cut down on volatile organic compound emissions by about 38 percent compared to traditional methods. What's interesting is that they perform just as well when it comes to resisting smears, showing less than 18% loss over time. They work great across temperature ranges from around 135 degrees Celsius up to 155 degrees too. This development addresses what used to be a real problem for companies trying to balance green initiatives with clear barcodes, especially where humidity levels tend to fluctuate quite a bit during printing operations.

Performance Comparison: Green vs. Conventional Wax/Resin Hybrids

Recent testing highlights three key differences:

- Abrasion Resistance: Eco-formulations show 12–15% faster wear in high-friction conveyor systems

- Chemical Tolerance: Green hybrids outperform petroleum-based counterparts in alcohol resistance (+23% durability), though they lag under oil-based solvents

- Adhesion Consistency: Bio-resins achieve 98% bond strength parity on recycled label stocks

A 2024 Material Compatibility Report confirms optimized formulations now meet ISO/IEC 15416 Grade A certification across 82% of common packaging materials.

Market Adoption and Industrial Applications of Sustainable Hybrid Ribbons

Since 2022, logistics firms have seen their usage of climate controlled warehouses jump by around 56 percent, mainly because these ribbons hold up better when dealing with all that condensation back and forth. The drug makers out there are now going for those special plant based resins on their blister packs, which helps cut down on chemicals getting into the products. For food processing plants, there's actually two good things happening here. First off, they meet those USDA organic requirements, and second, the labels stick properly even in super cold freezers that hit minus 30 degrees Celsius. Makes sense why so many are making the switch these days.

Regulatory Pressures and Corporate Sustainability Commitments Driving Change

Global Regulations Shaping Environmentally Responsible Labeling Practices

The EU's new CSRD rules are forcing companies to lay bare their environmental impacts, and businesses that fail to comply could end up paying hefty penalties amounting to 4% of their worldwide sales. Over in California, the Climate Corporate Data Accountability Act set for 2024 will require big corporations to account for all their indirect emissions too. This has created ripples throughout supply chains as manufacturers scramble to clean up their act. A recent look at industry trends shows something interesting happening in the packaging sector specifically. About six out of ten packaging firms accelerated their move toward eco-friendly materials last year alone, driven by these regulatory pressures. The shift isn't just about avoiding fines anymore it's becoming good business sense as consumers increasingly demand greener options.

How B2B Brands Are Integrating Green Printing into Their ESG Goals

Green printing has become one of the key components in ESG strategies for businesses that sell to other companies. According to recent industry data from 2024, around three out of four businesses prefer working with suppliers who use environmentally friendly thermal transfer ribbons. About half of these companies have also started implementing their own carbon pricing systems when making purchasing decisions. Many firms are overhauling how they handle packaging processes because retailers are increasingly focused on sustainability metrics. These scorecards often come with penalties for labels that can't be recycled. By addressing this issue, companies not only avoid potential fines but also move closer to achieving their net zero targets across the entire supply chain.

Future Outlook: The Evolution of Sustainable Thermal Transfer Ribbon Technology

Next-Gen Innovations in Circular Economy-Based Ribbon Design

The industry is moving toward closed loop systems now, and some reports say around 87 percent of ribbon parts actually get reused or repurposed according to the 2024 Circular Materials Report. We've also seen new formulas without polyester these days, which means ribbons break down completely at industrial composting sites after about a year. That helps tackle the problem of over 210,000 tons of plastic waste generated each year by traditional manufacturing methods. Companies are putting QR codes right on the cores too, so they can monitor how well things get recycled. Early tests show this tracking system has increased reuse rates by nearly 40 percent in some areas.

Long-Term Industry Projections for Green Thermal Transfer Solutions

Market analysts expect the sustainable ribbon sector to expand at around 7.5% annually until 2035, mainly because online retailers keep pushing for greener product labels. New hybrid options that mix bio-based waxes with recycled resins are starting to perform just as well as regular ribbons but cut volatile organic compound emissions down by nearly two thirds. According to an assessment released in 2025, almost three quarters of logistics companies intend to switch completely to environmentally friendly ribbons over the next eight years. This shift is happening faster thanks to smart sorting technologies that automatically separate out sustainable materials from conventional ones during processing.

Debating the Validity of Biodegradability Claims in Real-World Conditions

About 68 percent of so-called compostable ribbons pass those ASTM lab tests, but when we actually put them through their paces in real world landfills and compost facilities, only around 41% actually break down as promised. There's quite a gap between what happens in controlled environments and what occurs outside of them. Because of this problem, the industry has started implementing stricter certification rules that require materials to be tested across different humidity levels (between 30 and 90%) and temperatures ranging from minus 20 degrees Celsius all the way up to 45 degrees. Now there are third party auditors checking every step of the process from where the raw materials come from right through to how they get processed at the end of their life cycle. These checks make sense after research found nearly 30% of companies making biodegradable claims couldn't back up those assertions with complete evidence covering the entire product lifespan.

FAQs

What are traditional thermal transfer ribbons made of?

Traditional thermal transfer ribbons are usually made of plastic cores that do not break down and inks loaded with chemicals like phthalates.

Why is there a demand for sustainable alternatives in labeling?

The demand is driven by corporate ESG commitments and tighter regulations on hazardous materials, especially in sectors like healthcare where eco-friendly options have surged.

How do biodegradable thermal transfer ribbons work?

Biodegradable ribbons use plant-based resin blends and mineral-reinforced wax that decompose faster while maintaining print durability. They replace petroleum-based polymers with algae-extracted binders.

How are companies making ribbon production more sustainable?

Companies are switching to recycled PET cores and cellulose spindles, using thin-film architectures to reduce materials, and developing low-emission technologies to cut VOC emissions.

What are the challenges in achieving true compostability for ribbons?

The main challenges are balancing decomposition rates with long-term chemical stability while ensuring the ribbons remain durable in applications that require lasting legibility.

Table of Contents

- The Environmental Impact of Traditional Thermal Transfer Ribbon Production

- Innovations in Biodegradable, Recyclable, and Low-Emission Ribbon Materials

- Sustainable Wax/Resin Hybrid Solutions: Balancing Performance and Ecology

- Regulatory Pressures and Corporate Sustainability Commitments Driving Change

- Future Outlook: The Evolution of Sustainable Thermal Transfer Ribbon Technology

-

FAQs

- What are traditional thermal transfer ribbons made of?

- Why is there a demand for sustainable alternatives in labeling?

- How do biodegradable thermal transfer ribbons work?

- How are companies making ribbon production more sustainable?

- What are the challenges in achieving true compostability for ribbons?