Building 2, Dongfang Mao Commercial Center, Hangzhou, Zhejiang, China +86-18858136397 [email protected]

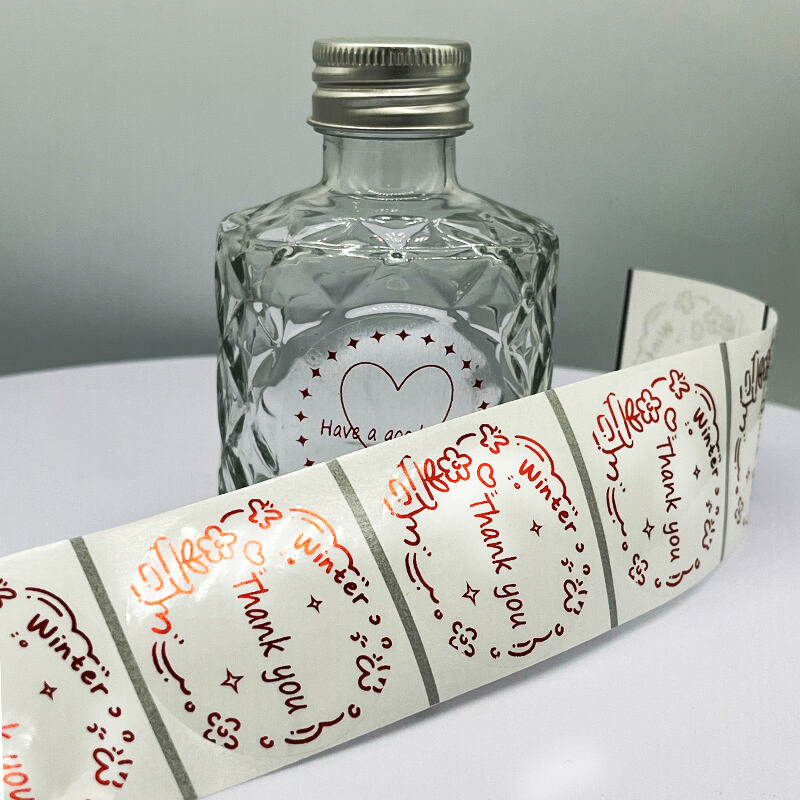

Metallic foil quality is a multi-faceted attribute defined by several critical performance parameters that directly impact production efficiency and the final aesthetic outcome. Superior quality foil is characterized by excellent opacity, ensuring complete coverage and a solid metallic appearance without any underlying substrate show-through. It must possess consistent and reliable release properties, allowing the metal and pigment layer to cleanly and completely transfer from the polyester carrier film to the substrate under the correct heat and pressure conditions. Strong adhesion is paramount, meaning the transferred foil layer bonds permanently to the surface without flaking or peeling off over time. Other essential quality indicators include scratch and abrasion resistance, chemical resistance (to alcohols, oils, or plasticizers, depending on the end-use), and lightfastness for products exposed to UV light. For example, a foil used on a premium spirit bottle label must exhibit high alcohol rub resistance to maintain its integrity during handling and consumption, while a foil on an outdoor product must resist fading. We implement a rigorous quality management system throughout our manufacturing process, employing spectrophotometers for color measurement, precision testers for adhesion and rub resistance, and controlled environmental chambers for stability testing. This meticulous attention to quality ensures that our clients experience minimal waste, fewer press stops, and consistently brilliant results on their production lines, ultimately protecting their brand reputation and reducing total production costs. To understand how our quality standards can meet your specific project requirements, please contact us for detailed technical data sheets and performance specifications.