Building 2, Dongfang Mao Commercial Center, Hangzhou, Zhejiang, China +86-18858136397 [email protected]

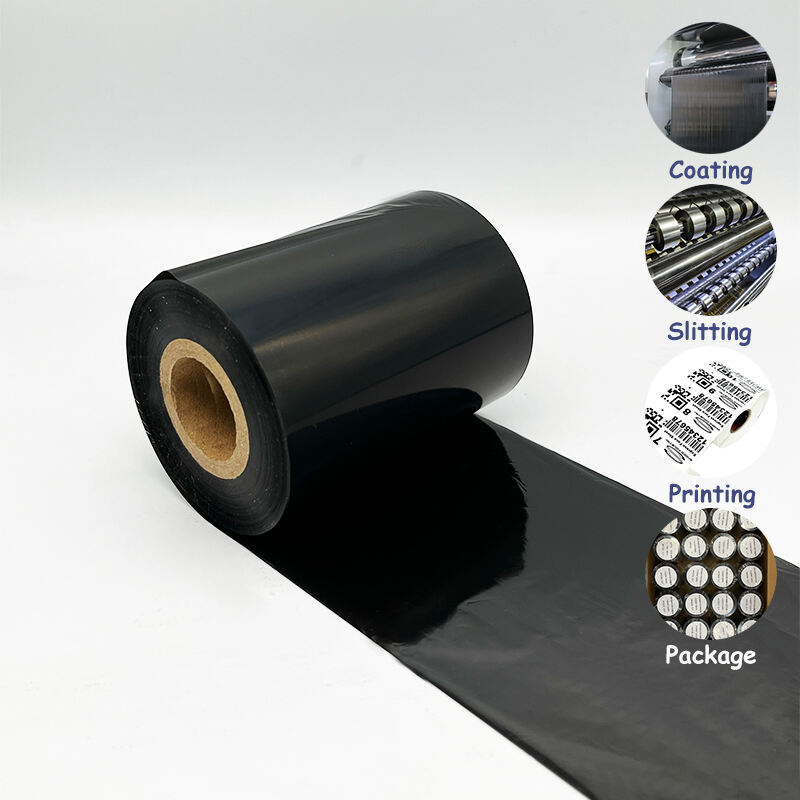

Barcode ribbon production blends precision coating, strict raw material control, and quality testing. It starts with selecting polyester base film for tensile strength and stable ink formulations (wax for paper, resin for durability). Precision roll coaters apply 5-15μm ink layers, with speed/pressure controlled to avoid defects. Wax ribbons dry at moderate temps; resin ones may use UV curing. High-precision slitting cuts to 10-110mm widths for printer compatibility. Quality checks include laser thickness gauges, tape-peel adhesion tests, and GS1 barcode scanning. Hangzhou Sinoco Industry Co., Ltd. uses ISO-certified facilities and 10-coater systems for batch consistency. It adapts to custom orders, like heat-resistant inks for electronics. Post-production, ribbons are wound on cores and moisture-sealed. This process ensures reliable ribbons for retail, healthcare, and more, meeting diverse printing needs.